Every you need to know about Yarn from History and picking the right Yarn for your next Crochet Project

Hello, and thanks for stopping by! Today I wanted to share some interesting information about yarn. We all take for granted when we go to our favorite store the fact we’ll have plenty of yarn to choose from. But have you ever wondered how it is made and what is the difference between the fibers used to create yarn? I have so I did some research and wanted to share what I found with you. I hope you find it as interesting as I did.

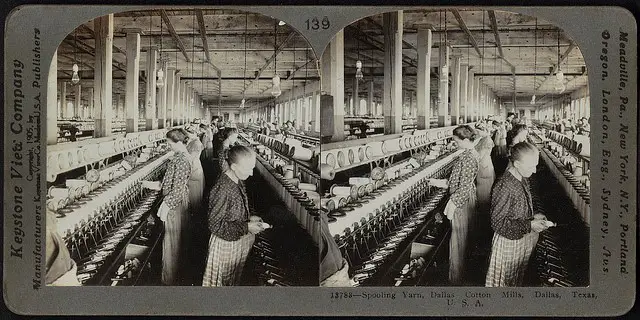

Spooling yarn, Dallas Cotton Mills, Texas

All yarn is made of several strands of material which are twisted together. Each strand is shorter than the yarn they form and is spun together to create the long filaments which make up yarn. Some continuous strands may require only twisting to create yarn, while other strands are put through a process known as texturing.

A very strong yarn will have a high degree of twist. Softer yarns have a low twist and a very high twist creates crepe yarn. Yarn is also classified by how many parts are used to create it. A single yarn is from one group of staple fibers, or filaments, twisted together. Two or more single yarns twisted together form ply yarns. Two or more ply yarns twisted together create cord yarns.

A Short History of Yarn

Antique Spinning Wheel

Ancient civilizations used cotton, silk, flax, and wool to create fibers and yarn. Fragments of a plaid-weave linen fabric have been found near Robenhausen, Switzerland, and date back to 7,000 years ago.

The Egyptians cultivated and used cotton to create fabric approximately 12,000 years ago. Fragments of cotton fabrics have also been found in Mexico, the southwestern United States and Peru dating back to 3500 B.C.

Cotton was not commercially popular in Europe until after the colonization of the New World. The Chinese have had silk culture since 2600 B.C. and silkworms were cultivated in the Byzantine Empire.

Synthetic fibers did not appear until the late 19th century. The first synthetic fiber was rayon which is made from cotton or wood fibers. It was developed in 1891 but was not produced commercially until 1911. Nylon was invented about half a century later with polyester following in its steps. Today we have several synthetic yarns to choose from as well as animal and plant fibers.

Yarn Fibers

Yarn is produced from three major fibers; animal, plant, and synthetic. Animal fibers include wool, alpaca, mohair, and silk. Plant fibers include cotton, hemp, linen, and bamboo. Synthetic fibers include acrylic, polyester, micro-fiber, and nylon. Each type of fiber has its benefits and can be used for many types of projects.

Sheep used to produce wool yarn

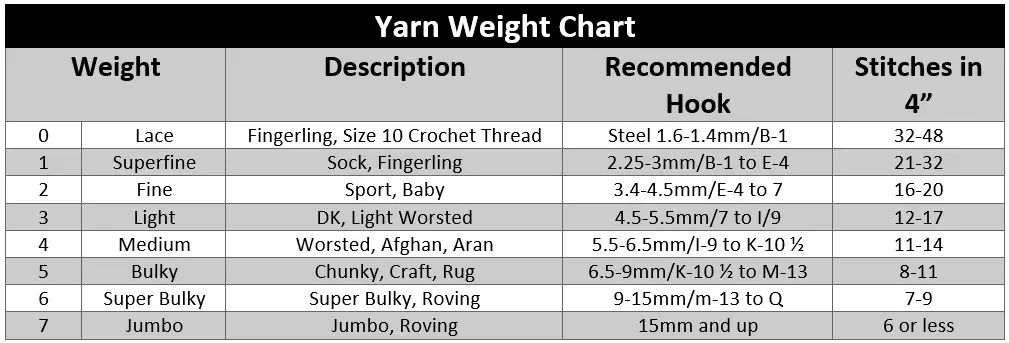

You can usually substitute one type of yarn for another as long as the weight and gauge match. Yarn comes in several weights ranging from fingerling to bulky.

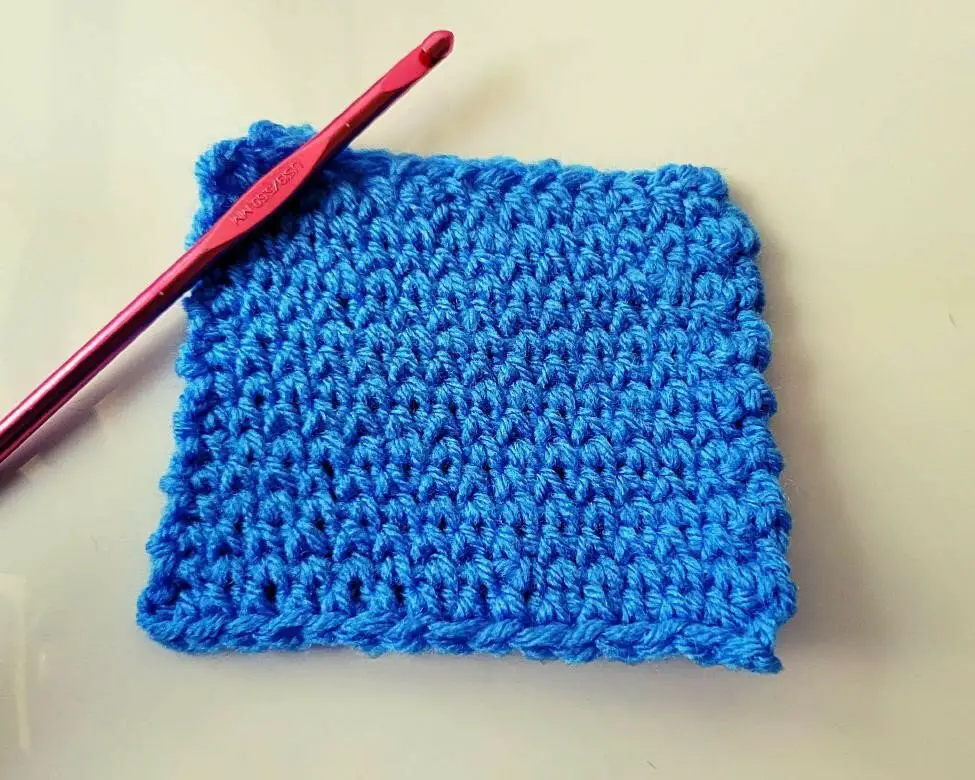

The type of stitches you use, single, half double, and double, all affect the gauge. These rounds are all crocheted from the same yarn, but three different stitches were used. Gauge refers to the number of stitches and rows in a four by four-inch swatch of crocheted fabric. For example, a medium weight (4) yarn should give you from 11 to 14 stitches across four inches using a size I/9 to K/10.5 hook. A thin fingerling yarn gives many more stitches, from 32 to 48 per four inches using small steel hooks. As you can see, gauge is important.

Yarn Manufacturing Today

While our ancestors used a spinning wheel and spindle, today’s commercial yarns are manufactured in large processing facilities. The three major processes used today are cotton, worsted, or long staple. Acrylic yarn can be produced using all three processes. Cotton yarn is produced in this manner:

First fibers arrive at the manufacturing site in bales. These are opened by hand or with a machine. Natural fibers such as cotton need cleaning, and synthetic fibers require only spinning. A picker may loosen up the fibers and clean them if necessary. Fibers may be blended to achieve a special application. Blending may be done during carding, drawing out, or during the formation of the lap. Each fiber is measured carefully for consistency.

Next, the cotton fibers must be carded. A carding machine with hundreds of fine wires separates the fibers and pulls them into a thin web of fiber. This web of fiber passes through a funnel-shaped device to create a ropelike strand of parallel fibers.

Combing is used when a finer, smoother yarn is produced. A comblike device arranges fibers into a parallel form. The shorter fibers then fall out of the strand leaving only the longer fibers.

The fiber mass created after combing is known as the sliver. Several slivers are used during the drawing-out process. The slivers are elongated by passing over a series of twisted and fed into large cans.

After drawing out the fibers are then twisted on a machine called the roving frame. This further elongates and twists the yarn.

Roving yarn

Most commercial facilities use ring spinning and open-end spinning to form yarn. In ring spinning, the roving is fed from the spool through rollers. This elongates the roving which then passes through the eyelet and down through the traveler. The traveler moves around a stationary ring from 4,000 to 12,000 revolutions per minute while the bobbin turns at a constant speed. By using the traveler and bobbin at the same time the yarn twits and winds in one operation.

Open-end spinning does not use the roving step. A stream of air feeds the sliver of fibers into the spinner and is delivered to a rotary beater which separates the fibers into a thin stream. This thin stream is then carried onto the rotor by a duct or tube through which air is passed. The sliver is then deposited in a V-shaped groove along the sides of the rotor. The twist is produced as the rotor turns. New fibers enter the rotor, are distributed in the groove, and are removed at the end of the formed yarn.

Once the yarn is formed into skeins, balls, and yanks it is distributed to stores. Yarn skeins are made to be drawn from the center while balls are made to be drawn from the outside. Yarn hanks must be wound into balls before use or else you’ll end up with a terrible mess.

Old school yarn winding by hand

I found a really interesting video about how yarn is made. Check it out: How Yarn is Made by The Crochet Crowd

Yarn Blocking Basics

While synthetic fibers do not need to be blocked, most animal and plant fibers look better blocked. Blocking opens up and relaxes the stitches. It is also important to shape a project such as a garment. You will need some blocking squares or thick towels and blocking pins or long dressmaker pins.

- Wet the fabric and then roll it up in a thick towel to remove the excess moisture. Do not ring it as this may damage the piece of crocheted fabric.

- Lay the fabric out on blocking squares shaping it gently.

- Begin pinning the fabric onto the squares starting at the edges. You may need to adjust the pins as you block the fabric to attain the correct shape.

- Let the fabric dry completely before you remove it from the blocks. The blocking will last until you wet or wash the fabric again.

You can also use a spray bottle of clear water to block smaller projects such as doilies.

- Pin the doily onto a blocking square or clean piece of cardboard covered with a towel.

- Lightly spray the doily with clear water.

- Let it dry completely before you remove it. You may want to press it with an iron and spray starch after you remove it from the blocking square. Be sure to read the yarn label to see if the fibers can be ironed before you do this last step.

Here is a doily before blocking:

Here is the same doily being blocked. Note how blocking really brings out the stitch definition.

Understanding a Yarn Label

When you choose a yarn for your project it is important to know what information can be found on a yarn label. Most manufacturers include the type of fiber used to create the yarn, the gauge, the weight, and care instructions.

On this label for Red Heart Super Saver Cherry Red yarn, we can see it is a medium-weight yarn with a weight class of 4. This gives a gauge of 12 single crochet stitches across 4 inches, and 15 rows per 4 inches. The crocheted fabric can be machine washed and dried but not ironed or bleached. You can find a complete list of laundry care symbols on the Lion Brand website. There is no dye lot, but if you find a yarn with a dye lot be sure to purchase enough yarn for your project so that the color stays consistent.

Here is a video by one of my favorite designers, Chandi at Expression Arts, on how to hand-spin yarn. How to Spin Yarn by Hand

End Notes

I hope you found this information about yarn interesting. What is your favorite type of yarn? Do you have a go-to brand? If you have any comments or questions, please leave a comment. I do check them and will answer as soon as I can. I’d love to hear from you. Got a suggestion for a blog? Leave a comment and let me know what you’d like to know about.

Thanks again for stopping by. Until next time, take care and keep on hooking!

If You Enjoyed this Article Please Share and Pin. It is Greatly Appreciated. 🙂